Boiler PCB faults can result in boiler failure and affect your home’s central heating and hot water supply. Read on to learn more about boiler PCB faults and whether replacements are worth it.

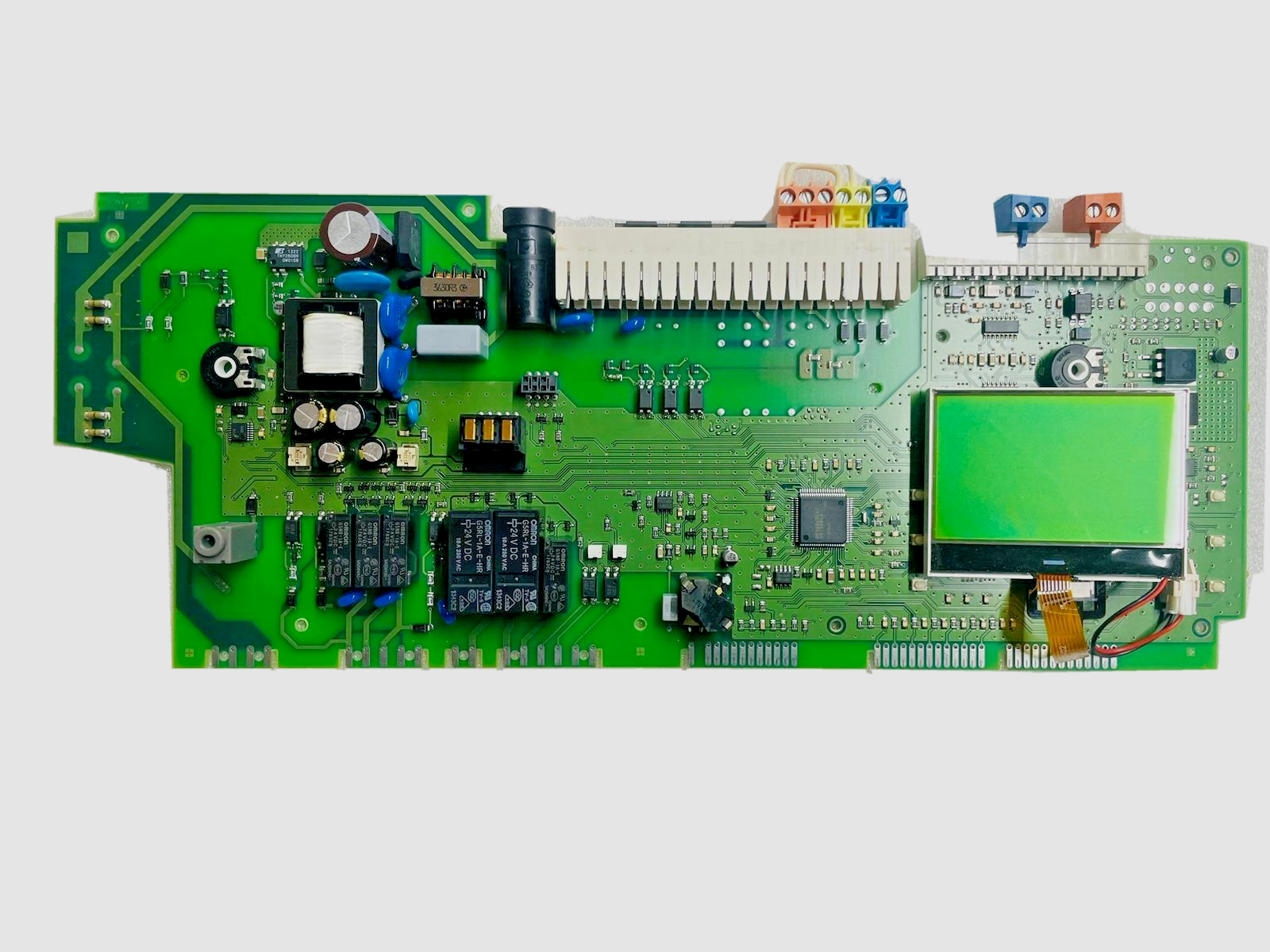

The printed circuit board (PCB) is a crucial component that serves as the brain of your boiler.

It controls each component, the communication between the parts, and the processes that ensure the boiler works as required.

Heating accounts for over 50% of your household energy bills, so you should address any issues that impact your boiler’s functionality as soon as possible, especially PCB faults.

Unfortunately, due to their complexity, PCBs are very expensive to replace. Therefore, if the part has failed completely and you have an old boiler, you may wish to consider whether replacing the entire boiler would be more cost-effective overall.

This guide explores everything you need to know about boiler PCB faults, including common signs, causes, and the next steps you should take.

Boiler PCB Faults Quick Takeaways:

- The printed circuit board, or PCB, acts as the boiler’s control centre and ensures communication and synchronizing of all electrical components.

- Common signs of boiler PCB faults include the display not powering on, a burning smell, a memory fault, wiring issues, and a faulty gas valve or fan.

- Causes of boiler PCB faults include age, water damage, boiler vibrations, and damaged or weak solder joints.

- A boiler’s PCB is costly; replacing it may cost around £500 on average.

- Sometimes, repairing or replacing frequent PCB failures can add up, so getting a new boiler with a fresh warranty may be more economical.

Are you wondering which boiler manufacturers performed best? Check out our best boiler brands guide for the full rundown, and if you are trying to determine who the best boiler installation company is, check out our Warmzilla and Boxt reviews.

What is a Boiler’s PCB?

The printed circuit board, or PCB, acts as the boiler’s control centre. It performs many tasks, including communicating between and controlling all electrical components.

It also synchronizes processes to ensure your boiler performs optimally and provides an uninterrupted heating and hot water supply.

The PCB also checks to determine if all parts work correctly for safety purposes. If the PCB detects any faults during the checks, it displays the relevant error code on the display window.

However, the PCB can become faulty, resulting in lockouts, potential breakdowns, and costly repairs since it can’t regulate the various boiler components.

Unfortunately, the PCB is one of the most expensive components of the boiler and can be costly to replace.

Therefore, buying a new boiler may be more cost-effective if your PCB cannot be repaired or is constantly malfunctioning.

Did you know your boiler’s efficiency can impact the energy it uses and, ultimately, your heating bill costs? Check out our guide to the best condensing boilers to learn more.

You may also find our review of the best eco-friendly boilers of interest.

What Should You Do If You Suspect Boiler PCB Faults?

It is important to consider safety when dealing with any boiler fault. Since the PCB is inside the boiler unit, you must call a Gas Safe registered heating engineer to investigate the matter further.

You should never attempt to open the boiler casing or tamper with its components. UK gas safety legislation requires that anyone carrying out work on gas appliances like boilers be Gas Safe registered.

As briefly mentioned, when a boiler shuts down, it will show an error code on the display window (unless it’s faulty!).

Once you have the error code, check the boiler’s manual to determine the source of the problem.

However, most faults will likely be inside the boiler and require a qualified professional.

The PCB instructs the boiler to shut down if a fault is detected. This prevents further damage to the boiler’s parts and protects the property from events such as a gas leak.

Do you have a common boiler problem? Check out our quick fix guide for boiler lockout, ignition faults, faulty diverter valves, and boiler timer issues.

What Are The Common Signs of Boiler PCB Faults?

Here are some common signs of boiler PCB faults:

No Power On The Display Panel

If the display panel does not light up at all, does not display the error code, or displays intermittently, the PCB could have a fault.

When nothing is shown at all, it’s likely power isn’t reaching the PCB, or it may have simply stopped functioning. It could also be a loose connection between the PCB and the display interface or a faulty display panel part.

Either way, you must call a Gas Safe registered heating engineer to diagnose and resolve the issue. They can investigate connection issues, make necessary repairs, or replace parts as required.

Burning Smell from Your Boiler

If you notice a burning smell coming from the boiler, intermittent problems when the boiler is running, or electrical failure fault codes, it could be a cause for concern.

The circuit board may have burned due to water leaking from the boiler, resulting in a faulty PCB.

The smell can result from moisture dripping onto the PCB connections and causing the board to burn.

You’ll need to call a Gas Safe registered heating engineer promptly so they can inspect the problem and prevent any further damage.

The engineer will open up the boiler, isolate and repair the leak if it’s the culprit, and make any necessary repairs to the PCB.

If the leak is severe or your boiler is too old, you may need to consider a boiler replacement.

Got a common boiler problem? Check out our quick fix guide for boiler lockout, ignition faults, faulty diverter valves, and boiler timer issues.

PCB Memory Fault

If your boiler’s display shows a memory fault error code, it could indicate that the PCB needs to be reset.

This sometimes happens following a new boiler installation or a PCB replacement.

If you’ve just installed your boiler, refer to the user manual and look for the associated product code. Entering the code will synchronize the boiler with the PCB, and the error code will disappear.

If you can’t locate the code or it doesn’t work, you’ll need to call a professional for assistance.

PCB Wiring Issues

All the electrical components are wired to the PCB to ensure efficient performance.

Connection issues can develop if the wires become loose, faulty, or stop working. Loose connections can significantly impact the operation of your boiler since the PCB won’t be able to send and receive signals from other components.

Until the problem is fixed, the components may stop working, and the boiler may shut down completely for safety purposes.

For example, if there’s a loose connection between the PCB and the fan, the boiler will shut down since it can create toxic fumes when on, and the fan must be working to remove them.

Call a professionally registered Gas Safe engineer immediately if you suspect wiring issues. They can investigate the internal wiring connections, undertake tests, and address any issues to ensure optimal performance and prevent potential safety hazards.

Faulty Gas Valve

The PCB powers the gas valve, a crucial boiler component. When you start your boiler, the PCB first confirms that the fan is working and will only send a signal to open the gas valve if the fan is running.

An electrical fault or wiring issue between the PCB and valve or fan can prevent communication and disrupt the sequence.

The valve may open intermittently or not at all. It may also open fully or partially when it should be shut.

This can cause the boiler to malfunction or shut down to avoid a potentially dangerous situation.

You should immediately call a qualified Gas Safe engineer to address the issue and ensure the gas valve functions correctly to avoid safety risks and further damage.

Recommended reading:

What Causes Boiler PCB Faults?

Age

The age of your boiler contributes to the risk of a fault developing with the PCB within the boiler.

With frequent use over time, the mechanical parts and boiler components, including the PCB, wear and tear.

Exposure to heat, moisture, and other environmental conditions can cause the PCB to deteriorate over time, resulting in malfunctions and faults.

Age-related wear and tear eventually takes its toll and can cause the PCB and other components to fail. Instead of constant repairs or replacements, installing a new boiler can be more cost-effective.

What size boiler is right for your home? If you are considering a combi boiler, it is largely determined by the number of radiators in your home.

Check out our complete guide to new boiler installation here if you are wondering about the best type of boiler for your home.

How much may a new boiler cost? Are you considering converting from a conventional to a combi boiler? Use our boiler installation cost calculator to get an estimation.

Water Damage to the PCB

Water can damage the PCB unit and other electronic components.

Leaks usually occur from a faulty heat exchanger or pump. They can get damaged over time due to wear and tear, creating hotspots and cracks that leak water.

Seals can break on old or strained pumps, allowing water to sip inside and damage the PCB unit and other boiler components.

You should report any leaks to a Gas Safety engineer and request immediate assistance to prevent further damage.

Boiler Vibrations

Although some slight vibrations are normal for a functional boiler, they can cause a fault when they become excessive.

The PCB and other components are fragile, and increased boiler vibrations can cause them to fall off or loosen the connections.

Excessive vibrations usually emanate from a faulty fan or pump. Monitor and report any excessive vibrations to a Gas Safety registered heating engineer for investigation.

Weak or Damaged Solder Joints

Components and connections are usually soldered on the PCB unit.

The solder can break off or deteriorate over time, causing the PCB to malfunction or break down.

The solder joints can also be weak or damaged due to improper installation, handling, or poor design and manufacturing, resulting in issues like short circuits or incorrect connections.

While a heating engineer can fix some solder issues on the spot, it does not guarantee that they will hold, and you may need to replace the PCB unit.

How Much Does A New PCB Cost to Replace?

A boiler’s PCB is costly, and replacing it may cost around £500 on average.

The exact costs can vary depending on the type, model, or brand of the unit and the complexity of the installation.

Different scenarios and locations may also feature different prices. Costs can vary based on where you live in the UK due to labour rates or parts availability.

If you have an older boiler that is out of warranty, the costs of repairing or replacing frequent PCB failures can add up, so it may be more economical to get a new boiler with a fresh warranty.

You must consider various factors, including the boiler’s age and the condition of other parts when making the decision.

You must also work with a qualified, experienced heating engineer to ensure proper installation and minimise future issues. They can also advise on the most suitable option.

Boiler PCB Faults Summary

The PCB plays a vital role in your boiler’s functionality. It allows all the components to communicate and work together in synchronicity to keep the boiler working as intended.

Identifying and addressing any issues that may arise with the PCB is crucial to maintaining efficient operations and a continuous supply of heating and hot water.

However, the more significant the issue, the more expensive the fix, especially if it recurs. If you’re dealing with frequent boiler PCB faults or the boiler is old and has other issues caused by wear and tear, investing in a new A-rated boiler can be more cost-effective.

Further reading:

- Smell of gas from boiler.

- Boiler leaking water.

- Boiler lockout.

- Boiler PCB faults.

- How to fix a faulty diverter valve.

- Compare BOXT boiler prices.

Sources and References

- https://energysavingtrust.org.uk/a-quick-guide-to-boilers/

- https://www.gassaferegister.co.uk/media/1449/who-can-legally-work-on-a-gas-appliance-factsheet.pdf