Last Updated on October 27, 2025

Boiler PCB faults can result in boiler failure and affect your home’s central heating and hot water supply. Read on to learn when to repair or replace your PCB for reliable heating in 2025.

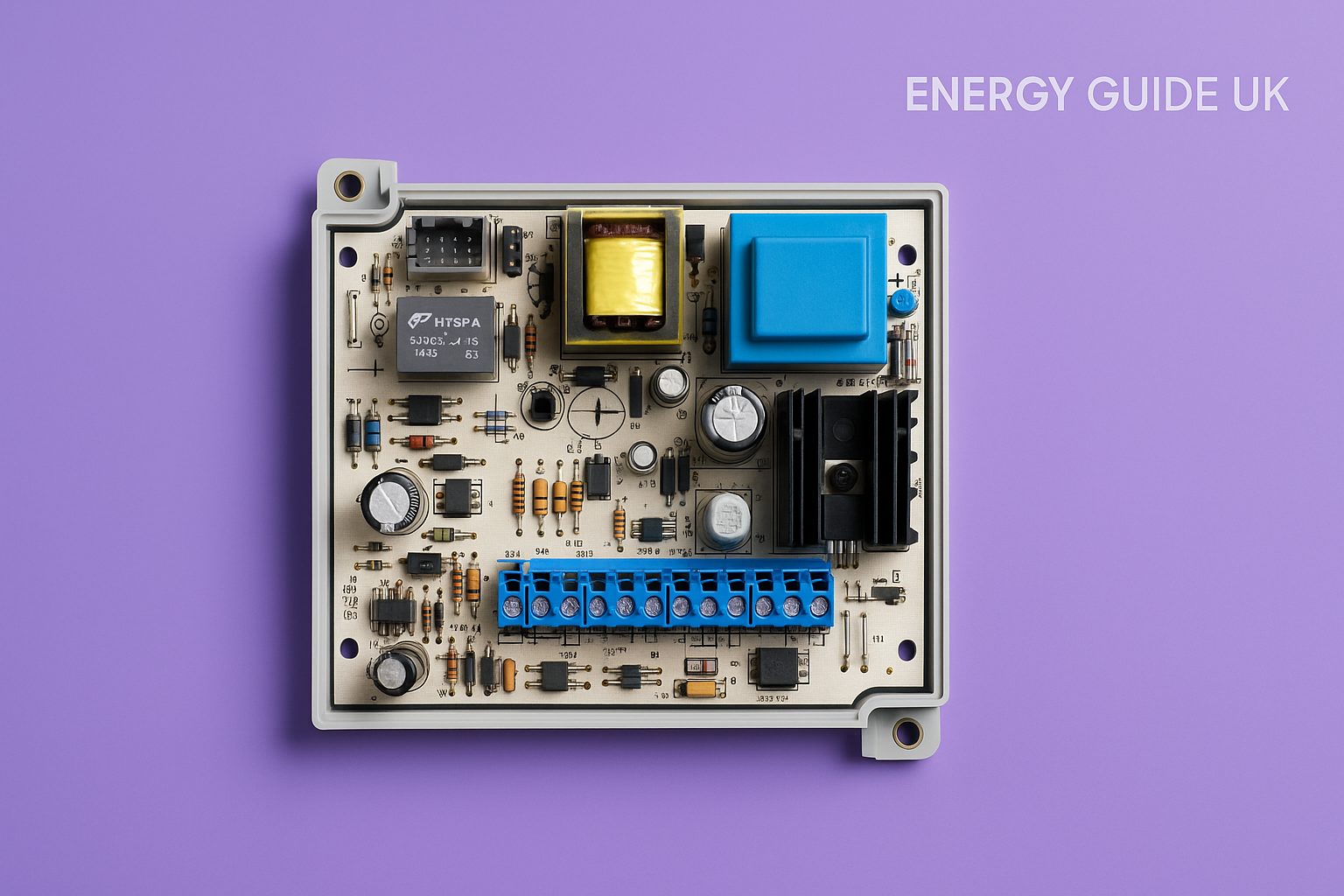

The printed circuit board (PCB) is a crucial component that serves as the brain of your boiler. It sends instructions to every other part of the system, so when it fails, the entire heating process comes to a standstill. What begins as a flickering display or an odd noise can escalate into a complete shutdown and an expensive repair.

Heating accounts for over 50% of your household energy bills, so you should address any issues that impact your boiler’s functionality as soon as possible, especially PCB faults.

The complexity of PCBs makes them expensive to replace when they fail. Knowing the early signs of PCB trouble, understanding costs, and taking quick, informed action can make the difference between a simple fix and a full replacement.

🔥 Need a New Boiler? Get a Fixed Price in 90 Seconds

Don’t waste time phoning around — Heatable shows you the best boiler deals online in under two minutes. No sales calls, no hidden fees, just instant prices from a trusted installer.

Get Your Fixed Price Now

Quick Takeaways on Boiler PCB Faults:

- The PCB is the control centre of your boiler. It manages ignition, safety functions, and power flow to all components.

- Faulty PCBs often cause flickering displays, shutdowns, or error codes. Early diagnosis prevents full boiler failure.

- Typical PCB repair costs range from £450 to £700 in the UK (2025). Minor repairs may be cheaper, while full replacements take one to three hours.

- If your boiler is more than 10 years old, replacement may offer better value. Modern A-rated models improve efficiency and lower bills.

- Annual servicing, fixing leaks promptly, and using surge protection are the simplest ways to prevent PCB damage and extend the lifespan of your boiler.

Are you wondering which boiler manufacturers performed best? Check out our best boiler brands guide for the full rundown, and if you are trying to determine who the best boiler installation company is, check out our Warmzilla and Boxt reviews.

What the Boiler PCB Does and Why It Matters

Inside your boiler lies a printed circuit board, often called the PCB, which functions as the system’s central control unit.

Every signal, from the thermostat, pressure sensor, and safety switches, passes through it. The board interprets those signals and sends precise instructions to the pump, fan, and gas valve to maintain safe combustion and steady water temperature.

When the PCB begins to fail, the timing and coordination that keep your heating system balanced start to break down. The boiler may misfire, lose power, or respond unpredictably to controls. In modern condensing boilers, even a small electronic glitch can trigger an automatic shutdown to prevent unsafe operation.

Think of the PCB as the nerve centre of your boiler. It decides when the flame should ignite, how much fuel should flow, and when the circulation pump should activate. If that decision-making process falters, the entire heating cycle collapses.

A working PCB ensures not just warmth but safety and efficiency. Regular servicing, stable power supply, and prompt attention to warning signs help prevent the costly disruption that a failed circuit board can cause.

Did you know your boiler’s efficiency can impact the energy it uses and, ultimately, your heating bill costs? Check out our guide to the best condensing boilers to learn more.

Common Symptoms of Boiler PCB Faults

A faulty PCB rarely fails without warning. In most cases, the problem begins with subtle changes in how the boiler behaves. Paying attention to these early signs can help prevent a complete breakdown and an expensive call-out.

Typical symptoms include:

- Blank or flickering display – The control screen may light up intermittently or go completely dark even when the power supply is stable.

- Random shutdowns – The boiler may start as normal, heat for a short time, and then shut down without warning.

- Error messages or flashing lights – Fault codes related to “communication” or “electronic control” often point to PCB issues.

- Unusual noises – Clicking or popping sounds before ignition can mean the board is struggling to coordinate electrical signals.

- Burning smell or scorch marks – Any sign of overheating inside the casing should be treated as an urgent safety concern.

Some boilers may also show misleading codes that suggest a sensor or fan issue when the real cause is a weak circuit connection. This is why only a qualified engineer should confirm a PCB fault. They can test voltage, inspect solder joints, and determine whether the problem lies in the board itself or in one of the components it controls.

When any of these warning signs appear, switch off the boiler and arrange a professional inspection. Continuing to operate a faulty PCB can damage other parts of the system and increase the total repair cost.

What Causes Boiler PCB Faults?

A boiler’s printed circuit board is a sensitive electronic component, and several everyday conditions can shorten its lifespan. Understanding these causes helps homeowners prevent damage before it leads to costly failure.

1. Age and Natural Wear

Over time, heat and vibration take their toll on delicate solder joints. After years of constant switching, connections can become brittle or break entirely, disrupting electrical flow through the board.

2. Water Damage

Leaks are one of the most common reasons for PCB failure. Even a small drip from a pipe or valve can introduce moisture into the casing, leading to short circuits or corrosion. Engineers often find discolouration or residue on boards exposed to damp conditions.

3. Power Surges

A sudden spike in voltage, whether from a lightning strike or unstable household supply, can overload the PCB’s circuits. Fitting surge protection in the home can prevent this type of damage.

4. Vibration and Mechanical Stress

Boilers with loose fixings or worn fans can produce continuous vibration that gradually loosens connectors and weakens solder points. Over months or years, this movement can cause the board to malfunction.

5. Poor Maintenance or Installation

Incorrect fitting, lack of servicing, or wiring faults may expose the PCB to excess heat or moisture. Regular maintenance ensures safe positioning, stable power connections, and early detection of potential faults.

Preventive care goes a long way. Scheduling annual servicing, keeping the boiler area dry and ventilated, and addressing minor leaks early are simple steps that can save hundreds of pounds in future repair bills.

What to Check Before Calling an Engineer

When your boiler shows signs of electrical trouble, it can be tempting to keep resetting it or searching for quick fixes online. However, a printed circuit board fault is a complex issue that requires professional attention.

Since the PCB is inside the boiler unit, you must call a Gas Safe-registered heating engineer to investigate the matter further. UK gas safety legislation requires that anyone carrying out work on gas appliances like boilers be Gas Safe registered, so you should never attempt to open the boiler casing or tamper with its components.

There are still a few safe checks you can do before arranging a service visit.

1. Confirm the Power Supply

Check that your fuse box has not tripped and that the boiler switch is firmly on. If other electrical appliances are working normally, the power supply is unlikely to be the issue.

2. Inspect for Leaks or Dampness

Look underneath and around the boiler for any signs of dripping water or moisture buildup. Even a small leak can damage the circuit board. If you see water, turn off the boiler and call an engineer immediately.

3. Observe the Display Panel

Take note of any flickering lights or error codes. Some codes will point directly to an electronic issue or PCB communication fault. Record them so the engineer can interpret the data quickly.

4. Try a Single Reset

Most boilers have a reset function. Use it only once. If the same fault reappears, switch the boiler off and avoid repeated resets, which can stress the board further.

5. Listen for Unusual Sounds

Popping, clicking, or a faint buzzing from the control area can indicate a fault with the PCB or connected relays.

- Is the fault limited to the PCB or linked to another component?

- Is the replacement part a genuine manufacturer board?

- Does the quoted cost include labour, VAT, and call-out fees?

- Will replacing the PCB affect my boiler warranty?

These questions help you understand the scope of the repair and whether it makes sense to invest in fixing the board or start planning for a full replacement. Gathering this information before authorising work can prevent unnecessary costs and ensure the repair is handled correctly.

Cost of Boiler PCB Faults Repair and Replacement in 2025

A faulty printed circuit board is one of the most expensive boiler problems to fix. The part is highly specialised, and engineers must often order it directly from the manufacturer. Labour costs are also higher because testing and refitting the board require precision.

In the UK, repairing or replacing a boiler PCB typically costs between £450 and £700 in 2025. The final price depends on your boiler brand, availability of parts, and regional labour rates. London and the South East usually sit at the top of that range, while repairs in the North of England or Wales can be 10% to 20% cheaper.

| Type of Work | Average Cost (Parts + Labour) | Typical Timeframe |

| Minor PCB Repair (solder or connector issue) | £250 – £400 | 1–2 hours |

| Full PCB Replacement | £450 – £700 | 1–3 hours |

| Full Boiler Replacement | £1,800 – £3,000 | 1–2 days |

If the part is still under manufacturer warranty, some or all of this cost may be covered, provided the boiler has been serviced annually by a Gas Safe engineer. Always ask for confirmation before work begins.

Extra expenses can arise if other components have been affected. A power surge, for example, might also damage the fan or ignition system. Engineers may charge a diagnostic fee (usually £60–£100) to determine the exact cause before proceeding with the repair.

When comparing quotes, check whether the price includes VAT, call-out, and follow-up testing. Transparent estimates should break down labour and part costs clearly. A trustworthy engineer will explain what caused the fault and whether replacing the board will restore long-term reliability.

Repair or Replace: Making the Right Choice

When a printed circuit board fails, the key decision is whether to repair the existing boiler or invest in a replacement. Both options can be sensible depending on the boiler’s age, efficiency, and overall condition.

Boiler PCB Repair vs Replacement

| Scenario | PCB Replacement Cost | Boiler Age | Best Option |

| Modern boiler under 5 years old | £450–£600 | Less than 5 years | Repair |

| Boiler between 8 and 12 years | £500–£700 | 8–12 years | Evaluate the full condition |

| The boiler is over 12 years old | £550–£700 | Over 12 years | Replace boiler |

If the boiler is fairly new, a PCB replacement often restores full function and can add years of reliable use. For older systems, however, other parts may already be wearing out. A replacement boiler might deliver greater long-term value and improved energy efficiency.

As a general rule, if the repair cost is more than half the price of a new boiler, replacement is usually the better investment. Modern A-rated boilers use less energy and can reduce annual heating bills by up to 20%.

Discuss both options with your engineer and ask them to assess the boiler’s overall condition, not just the board itself. Their advice will help you decide whether a repair is worthwhile or if upgrading to a newer, more efficient model is the smarter choice.

Check out our complete guide to new boiler installation here if you are wondering about the best type of boiler for your home.

How Engineers Diagnose Boiler PCB Faults

When a boiler stops working due to a suspected electronic fault, only a qualified Gas Safe engineer should carry out the inspection. Diagnosing a PCB issue involves both visual assessment and electrical testing.

Step 1: Visual Inspection

The engineer begins by examining the circuit board for obvious damage. Signs like scorch marks, melted components, or water residue often point to the source of the problem. They will also check the casing for moisture, rust, or evidence of leaks that may have caused short circuits.

Step 2: Testing Voltage and Connections

Next, they use a multimeter to test voltage levels and continuity across key points on the board. These readings help determine whether electricity is flowing as it should between components like the fan, gas valve, and pump. A failure in continuity often confirms a broken connection or burned-out section of the PCB.

Step 3: Checking Other Components

Because many boiler parts rely on the board to function, engineers also test sensors and wiring. Sometimes a faulty thermistor or fan can overload the PCB and cause it to fail. By checking the connected components, the engineer ensures the board is not being damaged repeatedly by another issue.

Step 4: Final Diagnosis and Advice

Once testing is complete, the engineer will confirm whether the PCB can be repaired or must be replaced. In some cases, the damage may be minor, such as a cracked solder joint, which can be fixed on-site. More often, a replacement is required because the cost of repairing a burned or corroded board outweighs the benefit.

Always request a service report detailing the findings. This record helps with warranty claims and ensures you understand the cause of the fault.

Got a common boiler problem? Check out our quick fix guide for boiler lockout, ignition faults, faulty diverter valves, and boiler timer issues.

Preventing Future PCB Faults

A boiler’s printed circuit board can last many years if it’s kept clean, dry, and well-maintained. Most PCB failures occur due to environmental factors rather than manufacturing defects, which means a few simple habits can dramatically extend its lifespan.

Keep the Boiler Serviced Annually

A yearly inspection by a Gas Safe engineer ensures that electrical connections are tight, internal components stay dry, and any early signs of wear are spotted before they cause a breakdown.

Fix Leaks as Soon as They Appear

Even a slow drip near the pipework or the pressure valve can create moisture inside the casing. Over time, this corrodes the PCB and its connectors. Addressing leaks quickly prevents both electrical damage and further mechanical wear.

Maintain Stable Pressure and Airflow

Boilers that run under fluctuating pressure or restricted airflow often work harder than they should. This increases vibration and strain on the circuit board. Regularly check that pressure sits within the manufacturer’s recommended range and that vents remain clear.

Protect Against Power Surges

Installing a surge protector is an inexpensive safeguard against voltage spikes. It shields the board from the kind of sudden electrical load that can burn out delicate circuits.

Keep the Area Ventilated

A boiler cupboard that’s too warm or humid shortens the lifespan of electronic parts. Keep it free from clutter and allow steady airflow around the unit.

Maintenance Checklist

| Preventive Step | Why It Matters |

| Annual Gas Safe service | Detects electrical wear before it causes failure |

| Repair leaks immediately | Stops moisture damage to the PCB |

| Monitor system pressure | Reduces mechanical strain |

| Fit surge protection | Prevents voltage-related burnout |

| Ensure good ventilation | Lowers risk of overheating |

Simple upkeep saves hundreds of pounds in the long run and helps the boiler maintain safe, efficient performance year-round.

Final Thoughts on Boiler PCB Faults

The printed circuit board inside your boiler is the control centre that keeps every component working in sync. When it fails, the entire system can shut down, leaving you without heat or hot water. Recognising the early signs of PCB problems, such as flickering displays, shutdowns, or error codes, allows you to act before a full breakdown occurs.

Prompt repairs are always worthwhile, especially since heating makes up more than half of your household energy use. For newer boilers, a PCB replacement can be a quick, cost-effective fix that restores full function. For older systems, replacement may offer better value through improved reliability and efficiency.

Annual servicing, immediate leak repairs, and surge protection remain the simplest and most effective ways to prevent PCB damage. With regular care and professional help, your boiler can stay safe, efficient, and dependable throughout the colder months.

FAQs on Boiler PCB Faults

How Much Does It Cost to Repair a PCB Board?

Repairing a boiler’s PCB usually costs between £250 and £400 in the UK. This covers minor issues such as loose connectors or small solder repairs. Costs vary depending on the boiler brand and how easily parts can be accessed.

How Much Does It Cost to Replace a PCB on a Boiler?

A full PCB replacement typically costs £450 to £700, including labour and VAT. Engineers may also charge a call-out fee if diagnostic testing is required before replacement.

How to Diagnose a Faulty PCB?

A qualified Gas Safe engineer will visually inspect the board for damage, check voltage and continuity with a multimeter, and confirm whether the fault lies within the PCB or another component, such as the fan or thermistor.

Can a Boiler PCB Be Repaired?

In some cases, yes. If the damage is minor, such as a cracked solder joint, engineers can perform a small repair. However, if the board is burned, corroded, or water-damaged, full replacement is the safest option.

What Are the Symptoms of a Boiler PCB Failure?

Typical signs include a blank or flickering display, clicking noises before ignition, random shutdowns, and electronic fault codes. In severe cases, the boiler may not power up at all.

How Long Does It Take to Replace a Boiler PCB?

Most PCB replacements take between one and three hours, depending on the model and accessibility. The engineer will usually test the system thoroughly afterward to confirm the repair was successful.

Sources and References

Energy Saving Trust – Boiler types explained

Gas Safe Register – WHO CAN LEGALLY UNDERTAKE WORK ON A GAS APPLIANCE?